Call us now

07971191840

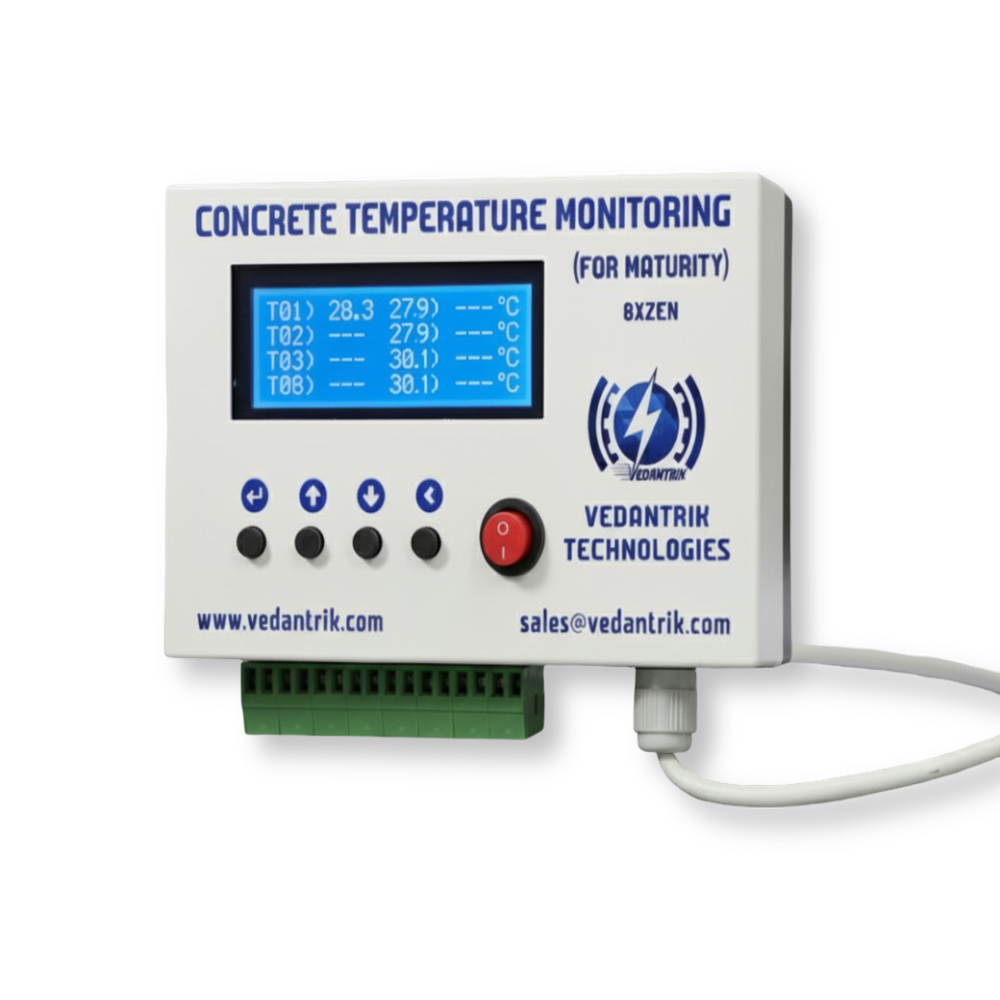

Mass Concrete temperature Monitoring system

Mass concrete temperature monitoring device developed by vedantrik technologies is an advanced temperature monitoring and data logging system specifically designed for mass concrete applications like raft, foundations, hot blocks and other mass concretes to prevent thermal stresses and micro cracking.

Wirelength Challenges in Mass Concrete Temperature Monitoring

In mass concrete applications, temperature sensors are typically embedded at multiple levels the top, middle, and bottom of the pour to accurately monitor temperature differentials during curing. However, in high-rise building foundations, the raft thickness can reach up to 3 meters or more, creating significant wirelength challenges.

As the sensors are placed deeper within the concrete, the distance between the sensors and the data loggers (which are usually installed at a controlled, accessible location) can exceed 5 meters. This extended wirelength can lead to inaccurate or higher temperature readings.

The commonly used RTD (Resistance Temperature Detector) thermocouples in concrete temperature monitoring are typically accurate only up to a cable length of approximately 5 meters. Beyond this distance, the increase in lead resistance can result in elevated or higher temperature readings. This is particularly problematic because the lead resistance is non-linear and not directly proportional to the cable length, making it difficult to apply standardized correction factors. Consequently, extended cable lengths introduce a significant source of error in temperature measurements.

But the device developed by vedantrik technologies for mass concrete temperature monitoring can give accurate temperature readings even if wirelengths are above 100 meters with accuracy of +/- 1 degree celsius.

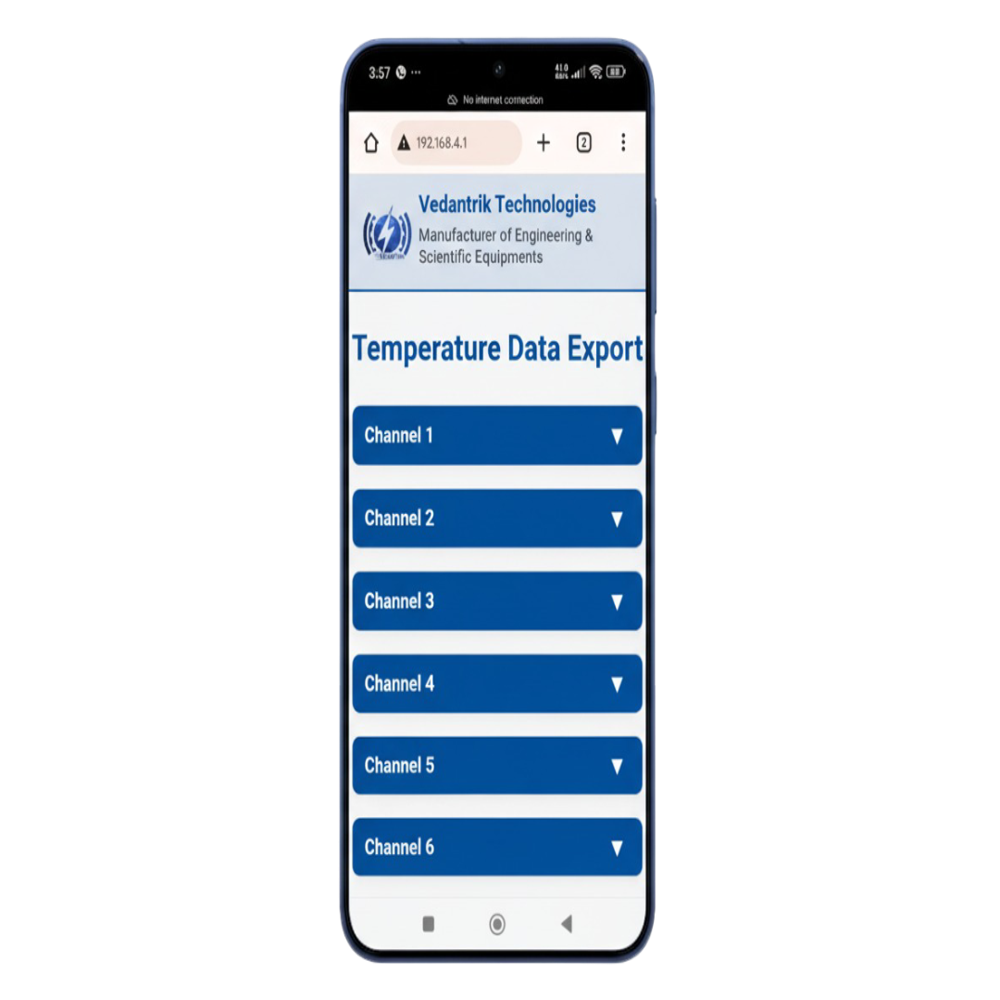

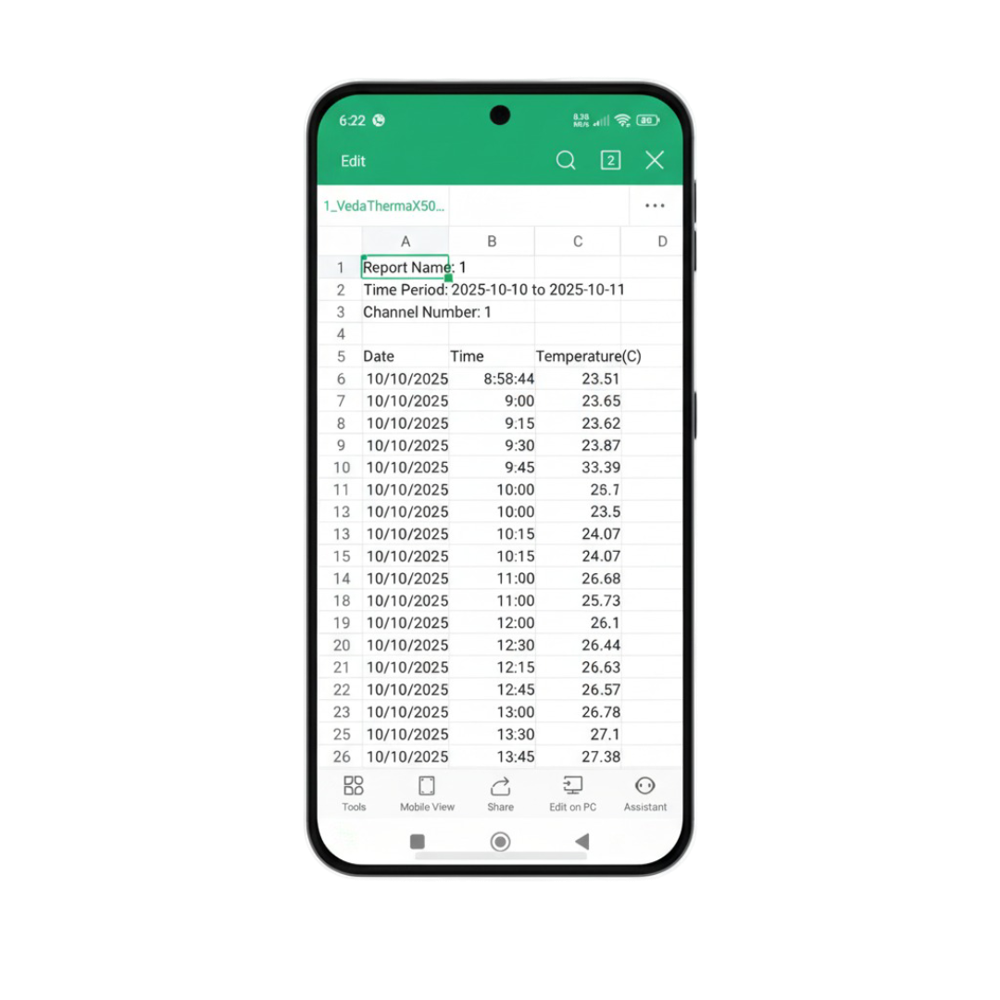

The device logs temperature data at user-defined intervals, with a standard recording interval of 30 minutes. The system utilizes high accuracy sensors, which are embedded in the concrete, during casting and remain in place throughout the curing process. These sensors feed temperature data to the devices internal storage, which can be accessed later wirelessly using mobile phone or laptop via wifi, the device supports Wi-Fi connectivity, allowing users to access and monitor data in real time through a PC, laptop, or mobile device. By providing accurate and timely temperature data, the system supports informed decisions regarding concrete strength development, enabling optimized construction schedules, timely formwork removal, and improved quality control in mass concrete applications.

Key Features:

Wide Temperature Sensing Range with High Accuracy

The device is equipped with high-precision sensors capable of measuring temperatures from the time of concrete casting through the entire curing period. The system accurately captures internal temperatures during the critical heat of hydration phase, providing essential data for quality control and structural safety. The sensors offer reliable performance, ensuring accurate temperature readings necessary for maturity-based strength estimation.

Automatic Logging with 30-Minute Interval (User-Defined Options)

The device records temperature data automatically at regular intervals, by default set to 30 minutes that can be configured to suit specific project requirements. This flexibility allows engineers to tailor the data collection frequency based on the concrete mix, ambient conditions, and structure type, optimizing both storage and monitoring needs.

Multiple Sensor Channel Options for Mass Concrete

The device comes with 16 channels, each can be connected to a different temperature sensor, allowing temperature monitoring at several points within a single pour. This is especially beneficial in mass concrete applications, where thermal gradients and differential heating can impact structural performance and cracking risk.

Onboard Storage and Wireless Data Access

Temperature data is stored locally on the device and can be retrieved via memory card. In addition, this device features built-in Wi-Fi connectivity, enabling users to connect through laptops, PCs, or smartphones to view real-time data, manage sensor inputs, and download detailed reports for documentation and compliance.

Concrete temperature directly affects hydration, setting, and strength development. Concrete Temperature Monitoring Devices help engineers track temperature changes during curing, ensuring optimal conditions are maintained.

In Mumbais climate, with varying temperatures and humidity levels, monitoring concrete temperature becomes vital. Vedantrik Technologies provides advanced monitoring systems that record accurate data, helping project managers maintain curing consistency.

By tracking temperature variations, contractors prevent issues such as thermal cracking, improper hydration, or delayed strength gain. These devices support better decision-making and improve the long-term durability of structures.

For precision concrete temperature monitoring devices in Mumbai, trust Vedantrik Technologies and enhance the quality of your construction projects.

Concrete temperature monitoring is a critical process in ensuring the structural integrity and long term durability of large concrete placements. Mass concrete refers to large volumes of concrete that require specific measures to deal with the excessive generation of heat from hydration and change in volume associated to minimize micro-cracking due to thermal stress.

In large scale projects continuous temperature monitoring becomes essential at the early stages after the placement, where thermal gradient and excessive heat can alter the development of micro-structures in concrete causing thermal cracks which are detrimental to the structural integrity of the concrete.

In the evolution of concrete from different phases, an exothermic reaction occurs between the cement and water which results in generation of heat called as heat of hydration.

The amount of heat generated primarily depends on the composition of the concrete mix design. In mass concrete, this heat is not able to dissipate quickly due to low surface area- to -volume ratio, resulting in the significant increase in internal temperature, sometimes exceeding 70C. This can become concerning because the difference in between the hot internal and cooler external surface can create a thermal gradient that can induce tensile stresses, potentially leading to thermal crack development.

Monitoring the temperature during these initial phases of development is crucial for quality control and compliance with various regulatory codes. As per the guidelines of ACI 301 and ACI 207.1R, the maximum temperature limit allowance ranges from 65C to 70C for internal temperatures and the difference between the ambient and internal temperature must not exceed or be less than 20C.

For continuous temperature monitoring, temperature sensors or thermocouples are embedded at different depths and locations within the concrete. The data is logged into a temperature monitoring device which allows the engineers to take immediate necessary actions if the temperature exceeds the safe limit. In addition the maturity method, as defined in ASTM C1074, can be used in parallel with temperature monitoring to estimate in-place strength gain. Since strength development is temperature-dependent, combining maturity and temperature data offers a comprehensive view of both thermal and structural performance.

In extreme cases or during hot weather concreting, pre-cooling (cooling the materials before mixing), post-cooling (using embedded cooling pipes through which chilled water is circulated), and surface insulation are employed to manage temperature rise. These methods aim to control the rate of temperature development and limit differential temperatures between the core and surface, thereby reducing thermal stresses.

Purpose of temperature monitoring in mass concrete:

Monitoring ensures concrete cures within the ideal temperature range. Too cold slows hydration, delaying strength gain; too hot accelerates it, reducing final strength and durability.

Temperature data helps estimate how quickly concrete is gaining strength. This guides safe timing for formwork removal, loading, or post-tensioning.

In mass pours, temperature differences between the core and surface can cause cracking. Monitoring helps manage cooling rates to reduce this risk.

In low temperatures, monitoring ensures concrete doesn't freeze before setting. It supports the use of heating or insulation when needed.

High heat can cause rapid moisture loss and shrinkage cracks. Monitoring allows for cooling methods or mix adjustments to maintain quality.

Real-time temperature data supports timely decision-making, helping avoid delays while ensuring the concrete has reached required strength.

Principle of Concrete temperature monitoring:

The thermal behaviour of mass concrete is governed by the exothermic hydration reaction, low thermal diffusion, low surface area-to-mass ratio, which in conjunction can lead to thermal cracking and long-term durability impairment, if not regulated with great concern. Temperature monitoring in mass concrete, therefore, becomes the base on understanding the thermal gradient induced during the hydration process, in conjunction with thermal & structural interaction that occurs due to differential thermal strain in between internal and external zones of the concrete mass.

The primary heat generation is derived from the exothermic hydration of portland cement phases, primarily tricalcium silicate, dicalcium silicate, since their heat evolution profiles are temporally variant and sensitive to mixture proportions, ambient temperatures, and presences of cementitious materials. The volumetric heat generation within the matrix leads to progressive elevation of internal temperature, which can rise beyond 65C to 70C in high cement contents while the outer exposed surface dissipates heat more efficiently via conduction, convection and by radiation, resulting in formation of a thermal gradient. The resulting thermal gradient then induces differential change within the concrete mass.

Internally, the concrete goes under thermal expansion during the peak hydration, whereas the outer surface being cooler, may undergo regional contraction, this creates difference in the hardness at various points in concrete. Upon the subsequent cooling, the core begins to shrink, but the surrounding hardened shell resists this contraction, preventing the volumetric movement, thereby imparting tensile stresses in the interior zone. These internal tensile stresses can significantly lower the development of compressive strength, leading to the formation of thermal induced cracks.

The concrete's natural low diffusivity contributes to slow temperature equalization across the cross-section, thus sustaining high temperature differentials over extended duration. Another critical aspect for temperature monitoring is the time-dependent nature of materials in concrete. Since the thermal strains are governed by both temperature changes and time-dependent mechanical properties, the process of temperature monitoring becomes essential in understanding the viscoelastic nature of the concrete.

Accurate temperature data, therefore, becomes essential to capture the real-time behaviour of the concrete to predict its stress-strain response under thermal loading. Furthermore, especially in mass concrete systems incorporating additives such as fly ash, slag, or silica fumes, kinetics of the hydration often get modified, contributing to prolonged heat evolution. Temperature monitoring in such systems must account for the synergistic thermal contribution of secondary reactions. Hence, concrete temperature monitoring becomes an important tool in the process of concrete strength development throughout the curing phase.

Components of Concrete temperature monitoring

1. Temperature Sensors: Embedded in the concrete to measure internal temperatures during curing. Common types include thermocouples, and digital sensors, all designed to withstand harsh construction environments.

2. Data Loggers: Records the temperature readings from sensors at regular intervals and logs the data in internal memory.

3. Wireless connectivity: System can connect with Mobile phone laptop PC using Wifi.

Standard procedure: Overview

1. Sensor Installation

Sensors are securely positioned within the reinforcement cage or attached to the formwork at pre-identified locations. Proper spacing and orientation are ensured to prevent sensor displacement during concrete placement. All wiring is routed through protective conduits or sleeves to safeguard against mechanical damage, moisture ingress, or interference during pouring and compaction operations. The integrity of the sensor installation is verified prior to the pour.

2. Concrete Placement and Monitoring Activation

Once the concrete is placed, the monitoring system is activated. Data loggers or wireless transmitters begin recording temperature at set intervals. The initial temperature readings immediately after placement help establish baseline values for curing analysis and thermal control.

3. Real-Time or Periodic Data Collection

Depending on the monitoring system employed, temperature data is downloaded wirelessly .

4. Data Analysis and Interpretation

Engineers interpret the temperature data in accordance with project-specific thermal control plans, ACI guidelines (e.g., ACI 301 for mass concrete), or maturity method standards (e.g., ASTM C1074). Data is evaluated to ensure curing temperatures remain within acceptable limits. If deviations are identified such as excessive thermal gradients or temperature peaks, corrective measures (e.g., insulating blankets, surface cooling, delayed formwork removal) are implemented.

Result Interpretation of Concrete Temperature Monitoring

The interpretation of concrete temperature monitoring data is critical to ensuring the structural integrity, durability, and safety of a concrete element, particularly in applications involving mass concrete, cold weather concreting, or accelerated construction schedules. The data obtained from embedded sensors must be systematically analyzed to assess compliance with design and curing requirements. Below are the key aspects considered during result interpretation:

1. Peak Temperature Evaluation

The maximum internal temperature recorded within the concrete mass is reviewed to ensure it remains within allowable limits, typically not exceeding 70C (158F) for most mixes, unless specifically engineered otherwise. Excessive peak temperatures may lead to deleterious effects such as Delayed Ettringite Formation (DEF), which can compromise long-term durability, and accelerated hydration, increasing the risk of early-age thermal cracking.

2. Temperature Differential Assessment

The temperature gradient between the core and surface of the concrete element is analyzed to identify the potential for thermal cracking. A commonly accepted threshold is a differential of 20C (36F); however, project-specific limits may vary based on structural geometry, restraint conditions, and material properties

3. Minimum Temperature Verification

Minimum recorded temperatures are reviewed to ensure they meet the threshold for proper cement hydration, especially in cold weather concreting. Typically, concrete must be maintained above 5C (41F) for standard mixes, unless modified with accelerators or heated curing methods. Temperatures below this threshold may cause delayed strength development, or result in incomplete hydration , compromising final performance.

4. Time-Temperature Curve Analysis

Time-temperature curves are plotted to visualize temperature evolution over time. These curves help determine the curing trends, such as rate of temperature rise and fall,timing of exothermic peak, which typically occurs within 2448 hours, and the rate of cooling, which should be controlled to avoid thermal stress buildup. Analysis of these curves supports engineering decisions regarding the timing of further construction operations.

5. Compliance Verification

All interpreted results are compared against the projects thermal control plan or governing specifications (e.g., ACI 301, ACI 207.1R, CSA A23.1). Any deviations from specified temperature ranges or curing conditions must be documented, and appropriate corrective actions should be recommended and implemented.

Factors Influencing Concrete Temperature Monitoring

Several variables influence the accuracy, reliability, and interpretation of concrete temperature monitoring. Understanding these factors is essential for implementing an effective monitoring system and ensuring valid data collection during the curing process.

a. Mix Design Characteristics : The type of cement, water-to-cement ratio, use of supplementary cementitious materials (SCMs), and presence of chemical admixtures significantly affect the rate and magnitude of temperature development in concrete. High-performance or mass concrete mixes, in particular, exhibit elevated heat of hydration, which requires close thermal management.

b. Ambient and Weather Conditions : External temperature, wind, and humidity influence both the surface and internal temperatures of concrete. In cold weather, the risk of freezing during early curing stages is critical, while in hot weather, rapid surface drying or heat accumulation can lead to thermal gradients and cracking.

c. Element Size and Geometry: Larger or thicker concrete sections (e.g., footings, piers, or mat foundations) retain more heat due to lower surface-to-volume ratios, which results in slower heat dissipation and higher internal temperatures. Conversely, thin sections cool more rapidly, increasing the risk of thermal differentials.

d. Sensor Type and Quality: The accuracy and sensitivity of the sensors used (e.g., thermocouples, fiber-optic sensors, or wireless maturity sensors) influence the precision of temperature readings.

e. Sensor Placement and Depth: Improper placement of sensors can lead to unrepresentative or misleading data. Sensors must be strategically installed at different depths (core vs. surface) and locations within the structure to capture thermal gradients and localized heating. Inconsistent or shallow placement may fail to reflect internal thermal conditions.

f. Insulation and Formwork Conditions: The presence of insulation materials, thermal blankets, or sealed formwork can slow down heat loss from the concrete, affecting its thermal profile. These protective measures are especially relevant in extreme weather but must be considered when interpreting the resulting temperature curves.

Technical Specifications:

Temperature Sensing range: 0C to 100C

Temperature Accuracy: 1C

Number of Channels: Up to 16 channels, allowing multiple sensor connections.

Maximum Sensor Lead Length: more than 100meters with accurate readings.

Report Generation: Automatic reports with temperature logs; download/export into your device.

Sensor : High-precision Temperature sensor for long-cable applications.

As a best Mass concrete temperature monitoring system Manufacturer in India we have supplied in Mumbai, Pune, Nashik, Aurangabad, Surat, Vadodara, Ahmedabad, Indore, Bhopal, Nagpur, Jaipur, Ludhiana, Ghaziabad, Delhi, Lucknow, Kanpur, Prayagraj, Patna, Ranchi, Dhanbad, Bengaluru, Hyderabad, Chennai, Coimbatore, Madurai, Visakhapatnam, Kolkata, and Srinagar.

Also we have supplied a range of products in Dubai, Abu Dhabi, the United Arab Emirates, Oman, Saudi Arabia, Kuwait, and Iran. We also serve clients in Singapore, Indonesia, Thailand, and other international locations.

Price:

Price 75000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Multicolour

Material : Mild Steel

Power Supply : Electric

Frequency : 50 Hertz (HZ)

Price 75000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Color : White

Material : Mild Steel

Power Supply : Manual

Frequency : 50 Hertz (HZ)

Price 75000.0 INR / Unit

Minimum Order Quantity : 1 Piece

Color : White

Material : Mild Steel

Power Supply : Electric

Frequency : 50 Hertz (HZ)

Price 75000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Color : White

Material : Mild Steel

Power Supply : Electric

Frequency : 50 Hertz (HZ)