Call us now

07971191840

Rebound Hammer

Based on the Schmidt mechanism, Vedantrik technologies has developed a compact, durable, and user friendly Rebound Hammer for reliable on-site concrete strength estimation. The instrument complies with various national and international standards like IS-516, ASTM C805, DIN 1048, and BS1881 to ensure consistent and accurate results.

The Rebound Hammer is used for non-destructive assessment of concrete quality and uniformity. During the test, the plunger of the hammer is pressed against the surface of the concrete, releasing the spring controlled mass that impacts the surface. The extent of rebound, measured as the rebound number, is directly related to the surface hardness of the concrete. Hence a higher rebound number indicates a harder and stronger concrete.

Each hammer is calibrated to ensure the rebound number accurately represents the stiffness of the spring and hardness of the concrete surface. The compressive strength of the concrete can be determined by correlating the average rebound number with the standard graph provided with the hammer. This enables engineers and site professionals to perform quick, reliable, and non-destructive evaluation of concrete strength directly on-site, helping in quality control and uniformity checks across structures.

About Rebound Hammer Test:

The rebound hammer test, also known as Schmidt hammer test, is a non-destructive testing (NDT) used to assess the compressive strength and surface hardness of the concrete. It was first developed by Ernst Schmidt in the 1950s and has since become one of the most common and widely used tests for compressive strength evaluation of concrete. The main instrument consists of a spring-controlled mass called a plunger that slides on a calibrated scale within the main body. When the plunger of the main body is pressed against a solid surface such as concrete, the spring loaded mass is released, striking the steel plunger in contact with the concrete surface. The mass then rebounds with a consistent and reproducible velocity, and the extent of the rebound is measured on the scale to get the rebound number. This rebound number is then empirically correlated to the compressive strength of the concrete, which is obtained using standard calibration charts or curves provided by National & International standardsIS-516, ASTM C805, DIN 1048, and BS1881.

The working of the rebound hammer test is based on the elastic rebound of the surface, which depends on the hardness and stiffness of the material being tested. A harder surface will cause greater rebounds, indicating the stronger and denser nature of the concrete, while lower rebounds indicate the opposite. The test is performed by holding the hammer perpendicular to the surface of concrete, ensuring good contact between the plunger and the surface. Multiple readings (usually 9-10 readings) are taken at different points on the same area, to get the average rebound value,for strength estimation. This practice minimises the error and improves the accuracy of the process. However it must be taken into consideration that the test primarily measures the surface hardness, which can be influenced by a variety of factors, and therefore, is an indirect method that requires correlation with laboratory test results.

The rebound hammer test can be used in both horizontal and vertical positions, but corrections must be applied depending on the orientation of the hammer, since the gravitational force influences the rebound reading. Furthermore, the calibration of the rebound hammer is also essential before testing to ensure accuracy and consistency in results. The calibration is typically done using a standard steel anvil. The interpretation of the test result is done using standard guidelines given by IS-516, ASTM C805, DIN 1048, and BS1881.

Purpose of Rebound Hammer test:

To estimate the compressive strength of the concrete without damaging the structure.

Helps identify variations in concrete quality across different areas.

To estimate the surface hardness of the concrete.

Allows comparison between old and new concrete structures for maintenance and repairs.

Principle of Rebound Hammer Test:

The rebound hammer test or Schmidt hammer test is fundamentally based on the principle of surface hardness measurement and the correlation between the elastic properties of concrete and its compressive strength. The underlying mechanism involves the kinetic interaction between a standardised mass, which is propelled by a calibrated spring mechanism, and the concrete surface. The extent to which this mass rebounds after the impact is quantified as rebound number, which serves as an indirect indicator of the materials elastic stiffness and surface hardness. These surface mechanical properties are directly linked to the concretes density, degree of compaction, and the continuity of the cementitious matrix, all of which in conjunction influence the compressive strength.

When the impact energy is applied on the surface of the concrete surface, a portion of this energy is absorbed within the near-surface zone, resulting in micro-elastic deformation and localised stress wave propagation. The remaining portion of the impact energy is restored as rebound energy, which propels the hammer backward. The magnitude of the rebound energy is controlled by the concretes capacity to elastically store and release strain energy. In denser and more homogeneous concrete, with well hydrated cementitious matrix and strong inter-facial transition zone, the deformation is majorly elastic and reversible leading to higher rebound value. In addition, the local stiffness of the impact region determines the proportion of impact energy that is elastically returned. The relationship can be conceptually linked to the materials stress-strain response under short duration.

Although the rebound process does not represent the true static compression, the local stress distribution beneath the contact point momentarily reaches the magnitude approach the true compressive strength of the surface layer. Consequently, the rebound number acts as an indirect measurement of the mechanical integrity, particularly within the depth of 10-20 mm at the contact surface.

The rebound value is sensitive to cementitious matrix, aggregate characteristics, along with hardness, angularity and gradation. Hence, the stress wave generated during the impact propagates through the heterogeneous micro-structures, encountering reflection and attenuation at the materials interface. Moreover the materials surface condition and moisture state, affects the damping characteristics of the concrete. Therefore, a dry concrete, due to reduced capillary saturation and higher stiffness at the inter-facial zones yield higher rebound number. Whereas a saturated concrete surface facilitates localised energy absorption at the damped regions lowering stiffness at the inter-facial zones yielding a lower rebound number. As such, the estimation of strength of concrete by rebound hammer method cannot be held to be very accurate and probable accuracy of prediction of concrete strength in a structure is 25 percent.

Measurement of rebound Hammer test:

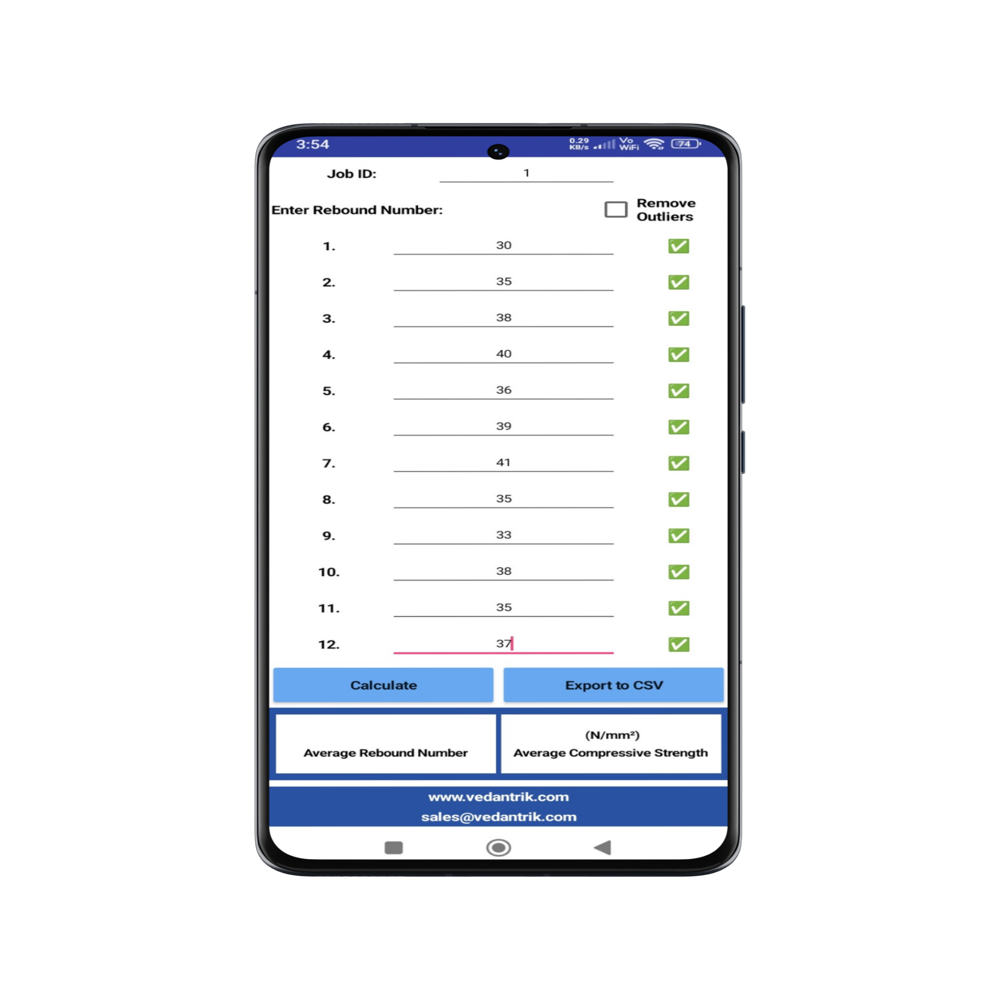

The measurement in a rebound hammer test is taken in terms of the rebound number, which indicates the hardness of the concrete surface. Multiple readings (usually 10 to 12) are taken on a selected area of the concrete surface. The average rebound number is then calculated after discarding any unusually high or low readings.

This average value represents the surface hardness of the concrete and is later correlated with compressive strength using a calibration chart or curve provided by the hammer manufacturer or established as per IS 13311 (Part 2):1992. Corrections are applied for the angle of testing (horizontal, upward, or downward), surface condition, and moisture content before interpreting the final result.

Components of rebound hammer

1. Rebound Hammer (Schmidt Hammer):

The main testing instrument contains a spring-loaded mass and plunger used to impact the concrete surface and measure the rebound number.

2. Concrete Surface (Test Area):

The prepared surface of the concrete member (wall, slab, beam, or column) on which the test is conducted.

3. Calibration Anvil:

A standard steel anvil used for periodic calibration of the rebound hammer to ensure accuracy and consistency of readings.

4. Correction Charts / Graphs:

Reference charts (provided by the manufacturer or as per IS 13311) used to adjust rebound numbers for testing angle (horizontal, vertical upward/downward) and surface condition, and to correlate them with compressive strength.

Standard procedure: Overview

1. Surface Preparation

The concrete surface should be clean, smooth, and free from dust, loose particles, or plaster. Rough or uneven areas should be leveled to ensure accurate readings.

2. Positioning the Hammer

Hold the rebound hammer perpendicular to the test surface. Note the orientation whether it's horizontal, vertical upward, or vertical downward as it affects the reading.

3. Taking Readings

Press the hammer plunger against the surface and release it to impact the concrete. Record the rebound number from the scale or digital display. Take at least 1012 readings in the test area and discard unusually high or low values.

4. Calculating the Average Rebound Number

Compute the average of the obtained readings to represent the surface hardness of the concrete.

5. Applying Corrections

Adjust the average rebound number for testing angle, surface condition, and moisture content using correction charts provided in the code or by the manufacturer.

Result interpretation of the rebound hammer test:

The average rebound number, after taking multiple readings and applying necessary corrections for testing angle, surface condition, and moisture content, is compared with a calibration chart provided by the manufacturer or various Standards to estimate the compressive strength. It is important to note that this method gives only an approximate value of concrete strength and is not absolute; the results can have an accuracy variation of 25% (as mentioned in IS 13311 (Part 2):1992), depending on factors such as concrete type, surface smoothness, and testing conditions. For critical assessments, rebound hammer results should be verified with core tests (IS 516).

Factors influencing the Rebound hammer test:

Concrete Age: Younger concrete is softer, giving lower rebound numbers.

Concrete Mix and Aggregate Type: Hard aggregates increase rebound; lightweight or soft aggregates reduce it.

Surface Hardness and Carbonation: Carbonated or overly hard surfaces give higher rebound values than the actual strength.

Moisture Content of Concrete: Dry surfaces produce higher readings than wet surfaces.

Testing Angle/Orientation: Upward, downward, or horizontal testing affects readings due to gravity.

Curing Conditions: Poor curing may reduce surface strength, affecting the rebound number.

Source of error in Rebound hammer test:

These are mistakes or procedural issues during testing that can lead to inaccurate readings:

Improper Surface Preparation: Dust, dirt, or uneven surfaces can distort results.

Incorrect Hammer Handling: Wrong angle, inconsistent pressure, or movement during impact.

Instrument Calibration Errors: Using a hammer that is not calibrated to the standard reference anvil.

Inconsistent Reading Locations: Testing over cracks, voids, or edges instead of a representative area.

Operator Error: Misreading the scale, recording errors, or insufficient number of impacts.

Technical Specification:

Range: 10N/mm2 - 70N/mm2

Standard Impact Energy: 2.207 J

Least Count: 2 rebound number

Weight (mass): 800g approximately.

Dimension: Dia 60mm, length 1 feet approximately.

As a best rebound hammer manufacturer in India we have supplied in Mumbai, Pune, Nashik, Aurangabad, Surat, Vadodara, Ahmedabad, Indore, Bhopal, Nagpur, Jaipur, Ludhiana, Ghaziabad, Delhi, Lucknow, Kanpur, Prayagraj, Patna, Ranchi, Dhanbad, Bengaluru, Hyderabad, Chennai, Coimbatore, Madurai, Visakhapatnam, Kolkata, and Srinagar.

Also we have supplied a range of products in Dubai, Abu Dhabi, the United Arab Emirates, Oman, Saudi Arabia, Kuwait, and Iran. We also serve clients in Singapore, Indonesia, Thailand, and other international locations.

Price:

Price 25000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Industrial

Warranty : Yes

Color : Multiple

Weight : 1 Kilograms (kg)

Price 25000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Industrial

Warranty : 1 Year

Color : Silver

Weight : 1 Kilograms (kg)

Price 25000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Industrial

Warranty : 1 Year

Color : Silver

Weight : 1 Kilograms (kg)

Price 47000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Industrial

Warranty : Yes

Color : Multiple

Weight : 22 Kilograms (kg)