Call us now

07971191840

Ultrasonic Pulse Velocity Meter:

The Ultrasonic Pulse Velocity (UPV) test is a widely used non-destructive testing method for assessing the quality, integrity, homogeneity and internal conditions of the concrete. The test is fundamentally based on measuring the velocity of the ultrasonic pulse as it travels through the concrete medium. The velocity of the sound waves in concrete depends on its density, homogeneity and internal continuity, therefore , any defects such as cracks, voids, and honeycombing will affect the travel time and thus the calculated velocity.

In UPV an electroacoustical transducer produces a high frequency electrical pulse which is converted into mechanical wave (ultrasonic pulse),and this pulse propagates through the concrete and is detected by a receiver which converts it back into an electrical signal. The time of travel (t) of the pulse between the transducer and receiver is measured precisely using an electronic timer. The pulse velocity (v) is then calculated using a general formula v=l/t, and the result is expressed in kilometers per second (Km/s).

The test can be conducted in three ways; direct, semi-direct and indirect transmission depending on the site accessibility. In direct transmission the emitter and receiver are placed on opposite faces of the concrete, allowing the pulse to travel directly through the material. Since the pulse travels the shortest distance, it gives the most accurate and consistent results. In a semi-direct method the emitter and receiver are placed at right angle or adjacent surfaces, where the pulse travels diagonally through the concrete. This method is particularly used when only two adjacent surfaces are available. Finally, in the indirect method both emitter and the receiver are placed on the same surface. Although this arrangement gives lower velocity value, it is still useful for locating cracks and defects when only one side is accessible.

To ensure reliable readings, the contact surface between the transducers and the concrete must be applied with a couplant such as grease, petroleum jelly, other gel based materials to eliminate air gaps and improve the transmission of the ultrasound. Interpreting the UPV result involves comparing the calculated velocity with the standard reference values provided by IS 516 (Part 5/Sec 1): 2018 and ASTM C597. However, these values may vary depending on the mix design, aggregate type, and environmental conditions. Therefore the results of UPV must also be compared with other NDT methods , for evaluating uniformity, quality and deterioration in concrete.

Purpose of Ultrasonic pulse velocity test:

To evaluate the quality and uniformity of the concrete.

To detect internal cracks, voids, honeycombing, or deterioration

Can be used to estimate the strength of concrete indirectly, when correlated with a compressive strength test.

Assess homogeneity between different parts of a structure.

Principle of Ultrasonic pulse velocity test:

The ultrasonic pulse velocity test works on the principle of elastic wave propagation through heterogeneous solid media and its correlation with the mechanical integrity, density,and homogeneity of concrete. It exploits the behavior of longitudinal stress waves (P-waves) that transverse the material in response to a transient mechanical excitation of ultrasonic pulse frequency, typically ranging from 20 kHz to 150 kHz. The fundamental concept is that the velocity of propagation of these waves is intrinsically governed by the mass density of the medium, which are, in turn, influenced by the material's microstructural composition, degree of compactness, presence of micro-cracks, elasticity, and the quality of the inter-facial transition zone between the aggregate and cement paste.

In concrete, which is an inherently heterogeneous composite the relationship between composition, density and its elasticity becomes more complex due to scattering, reflection, refraction and mode of conversion effects that occur at the boundaries of different constituent phases. However, effective pulse velocity observed in concrete can still be regarded as a representative parameter of its overall stiffness and structural continuity. The propagation of ultrasonic pulses in concrete is strongly influenced by the acoustic impedance miss matches between the constituent materials. It dictates the degree of transmission and reflection of the wave at the phase boundary. When the ultrasonic pulse encounters an interface between the medium of differing impedance, part of the wave energy is reflected and the rest is transmitted.

Hence, any discontinuity due to cracks, voids, or poorly bonded interface introduces additional reflection and scattering phenomena, effectively increasing the transmit time of the pulse between the two points and thereby reducing the apparent e recorded velocity. The upv therefore serves as a macroscopic indicator of the structural integrity of the concrete. The transmit time of the ultrasonic pulse depends on both the elastic property and path continuity.

In a well hydrated cement matrix, the inter-granular complexes are continuous and stiff, giving higher elastic moduli which in turn yields higher pulse velocity. In contrast, micro-cracking due to shrinkage, thermal stress, or load-induced damage disrupts this continuity, effectively reducing the effective stiffness and thus the propagation velocity. In essence, the UPV test is an application of the relationship between the wave propagation velocity, elastic nature of the concrete which is dictated by micro-structural uniformity and continuity.

Measurement of Ultrasonic Pulse Velocity test:

The test is based on measuring the time taken (T) by an ultrasonic pulse velocity to travel through a known path length (L). The pulse velocity (V) depends on the elastic properties of the concrete, and is calculated by the following formula:

V=L/T

Where,

V = Velocity of the pulse (m/s or km/s)

L = Path length between the two Transducers (emitter and receiver)

T = Transit time of the pulse (s)

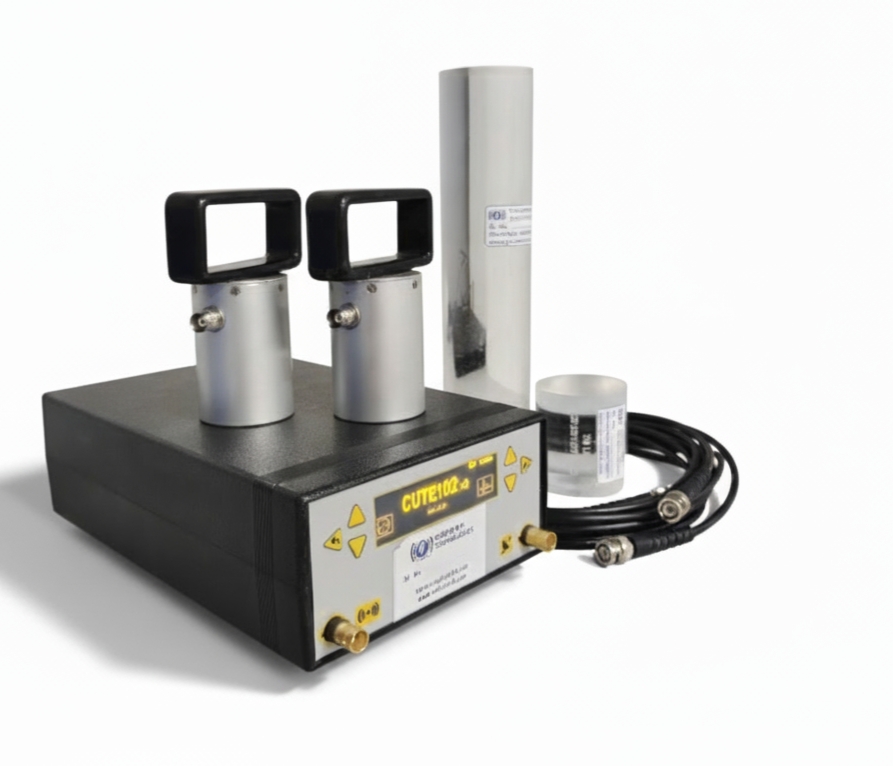

Components of Ultrasonic Pulse velocity test:

The main components of an Ultrasonic Pulse Velocity testing system are:

Main Unit (UPV Tester): This is the central device that controls the entire test. It generates electrical pulses, measures the transit time of ultrasonic waves, and displays or records the pulse velocity. It also supplies power to the transducers and processes the received signals.

Transducers (Transmitter and Receiver): The transmitter converts electrical pulses into ultrasonic waves, and the receiver converts the returning waves back into electrical signals.

Couplant: A gel, grease, or paste applied between the transducers and the concrete surface to ensure proper transmission of ultrasonic waves by removing air gaps.

Connecting Cables: Connect the transducers to the main unit, allowing transmission and reception of electrical signals.

Standard Procedure for Ultrasonic Pulse Velocity (UPV) Test

The Ultrasonic Pulse Velocity (UPV) test is carried out according to IS 516 (Part 5/Sec 1): 2018 or ASTM C597 to determine the quality, uniformity, and integrity of concrete. The following steps outline the standard testing procedure:

Application of Couplant on the surface

A thin layer of Couplant, such as petroleum jelly, grease, or gel, is applied to the contact area between the transducers and the concrete surface. The Couplant eliminates air gaps and improves the transmission of ultrasonic pulse from the transducer into the concrete, ensuring more accurate reading.

Positioning of the transducer

The transmitting and receiving transducers are positioned on the concrete using one of three arrangements depending on accessibility. In direct transmission the transducers (emitters and Receivers) are placed opposite faces of the concrete specimen, it is considered the most accurate method. In Semi-Direct transmission the transducers are placed on adjacent faces, while in indirect (Surface) transmission both transducers are placed on the same face (least accurate but useful when only one face is accessible). Proper alignment of the transducers ensures accurate measurement of pulse travel time.

Measurement of the Path length

The distance between the centers of the two transducers is measured carefully using a measuring tape or scale. This measured distance represents the path length (L) through which the ultrasonic pulse travels.

Recording the transit time

The main unit of the UPV is switched on to generate an ultrasonic pulse through the transmitter. The pulse travels through the concrete and is received by the receiver. The time taken by the pulse to travel this distance, known as the transit time (T), is displayed on the device. Multiple readings are taken at each point, and the average value is used for accuracy.

Result interpretation of Ultrasonic pulse velocity test:

The velocity of ultrasonic pulses through concrete depends on its density and elastic properties. The quality of concrete can therefore be classified as follows (as per IS 516 (Part 5/Sec 1): 2018 and ASTM C597):

|

Concrete Quality |

Condition |

|

|

> 4.40 |

Excellent |

Very good quality, dense, and uniform concrete |

|

|

3.75-4.40 |

Good |

Good quality with negligible voids or cracks |

|

|

3.0-3.75 |

Medium |

Fair quality, may contain minor defects or variations |

|

|

< 3.0 |

Doubtful |

Weak, porous, or damaged concrete |

The quality of concrete can be assessed using Pulse Velocity measurements in kilometers per second (km/s). Concrete with a pulse velocity >4.40 km/s is considered Excellent, indicating very good quality, dense, and uniform concrete. Pulse velocities in the range of 3.75 to 4.40 km/s correspond to Good concrete, which is of good quality with negligible voids or cracks. When the pulse velocity falls between 3.0 and 3.75 km/s, the concrete is rated as Medium, meaning it is of fair quality and may contain minor defects or variations. Concrete with a pulse velocity < 3.0 km/s is considered Doubtful, as it is likely weak, porous, or damaged.

Factors Influencing Ultrasonic Pulse Velocity (UPV) Test

Several factors can affect the accuracy and reliability of the UPV test results. These factors influence the speed at which ultrasonic waves travel through concrete:

Moisture content in the specimen:

Concrete that has higher moisture content allows ultrasonic pulses to travel faster because water fills the pores, improving transmission. Whereas, dry concrete generally gives lower pulse velocity readings

Path length and Geometry:

Very short path length or irregularly shaped specimens can lead to measurement inaccuracies, as the pulse may not travel uniformly through the material.

Concrete Mix and Density:

Denser and more homogeneous concrete provides higher velocities, while concrete with voids, honeycombing, or poor compaction show lower velocities

Surface condition and Couplant application:

Rough or uneven surfaces can cause poor contact between the transducers and the concrete. Hence, proper application of couplant is essential to ensure accurate readings.

Sources of Errors in Ultrasonic Pulse Velocity (UPV) Test

Poor surface contact:

Inadequate use of couplant or rough surface can lead to air gaps between the transducer and concrete, increasing signal loss and measurement errors.

Incorrect path length measurement:

Errors in measuring the distance between transducers directly affect the calculated pulse velocity.

Equipment calibration errors:

If the UPV testing device is not properly calibrated, the recorded transit times may be inaccurate.

Improper transducer placement:

Misalignment or unstable positioning of transducers can cause inconsistent readings.

Electrical or signal interference:

External vibrations, electrical noise, or poor signal connections can distort the received signal and lead to faulty timing measurements.

The Ultrasonic Pulse velocity Meter by Vedantrik technologies is a non-destructive testing (NDT) instrument designed to evaluate the quality, uniformity and integrity of concrete. It works by sending the ultrasonic pulses through the concrete via transmitting transducers, the pulses travelling through the material are then detected by receiving transducers on the opposite or adjacent surface. The device measures the transit time of pulses, and displays the values on the digital screen. Using the path length between the transducer, the velocity of the pulses can be calculated, which directly reflects the homogeneity, and presence of defects such as voids, cracks and honeycombs in the concrete. Designed for field and laboratory use, the device is portable and capable of testing path length up to 3 meters. To further enhance the measurement reliability, it includes a burst mode feature, which averages multiple ultrasonic pulses to provide stable readings, and a freeze function, that locks the reading on the display for convenience during the testing. Additionally, the android mobile applications enable indirect-mode calculations, streamlining workflow for engineers and quality control personnel. Lightweight, portable, and robust with a plastic housing, the Vedantrik UPV meter combines modern features with practical usability, making it a versatile and cost-effective solution for structural health monitoring, concrete quality assessment, and non-destructive evaluation of construction elements.

Key features:

Burst Mode for Stable Readings

In Burst Mode, the device transmits multiple ultrasonic pulses over 56 seconds and automatically averages the readings. This process minimizes fluctuations and ensures accurate, consistent results every time.

Reading Hold (Freeze Function)

The instrument automatically freezes the reading on display even after the transducers are removed, allowing ample time for users to record or review data without losing results.

Android App Connectivity

Comes with a dedicated Android application for easy indirect mode velocity calculation and graph plotting as per IS 516 standards. The app provides a user-friendly interface for data analysis, reporting, and sharing test results on the go.

High Storage Capacity

Designed with a built-in record and storage facility for up to 1,000 readings, ensuring convenient data logging during large-scale testing operations or multiple project sites.

Long Operational Backup

Powered by an in-built rechargeable battery, the device delivers extended operational backup, ensuring uninterrupted performance even in field conditions where power availability is limited.

Lightweight and Compact Design

Housed in a durable ABS plastic enclosure, the unit is lightweight, compact, and easy to handle, making it ideal for both laboratory and on-site testing applications.

Technical Specifications:

Measurable path length: 3-4 meters in good quality concrete.

Time measurement range: 0.1-9999.9 s.

Measurement parameters: Time and Velocity.

Time base:- 10MHz Quartz.

Frequency of Transducer: Standard 54KHz (Nominal).

User interface: OLED Display, keypad and PC interface.

PC Interface: Measurement log download.

Operator Adjustment: Calibrating using Calibration rod.

Battery Operating capacity: 8 Hrs. maximum.

Operating Temperature range: 0-50oC.

Size: W-180mm x H-55mm x D-240mm.

Weight: 1.90 Kg

As a best Ultrasonic Pulse Velocity Meter Manufacturer in India we have supplied in Mumbai, Pune, Nashik, Aurangabad, Surat, Vadodara, Ahmedabad, Indore, Bhopal, Nagpur, Jaipur, Ludhiana, Ghaziabad, Delhi, Lucknow, Kanpur, Prayagraj, Patna, Ranchi, Dhanbad, Bengaluru, Hyderabad, Chennai, Coimbatore, Madurai, Visakhapatnam, Kolkata, and Srinagar.

Also we have supplied a range of products in Dubai, Abu Dhabi, the United Arab Emirates, Oman, Saudi Arabia, Kuwait, and Iran. We also serve clients in Singapore, Indonesia, Thailand, and other international locations.

Price:

Price 295000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Material : MS

Color : Black Grey

Features : Good Quality

Usage : Industrial

Price 294998.0 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Mild Steel

Color : Black Grey

Features : Durability, Portable

Usage : Industrial

Price 295000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Mild Steel

Color : Black Grey

Features : High quality

Usage : Industrial

Price 294998.0 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Mild Steel

Color : Black

Features : Durability, Portable

Usage : Industrial