Call us now

07971191840

Rapid Migration Penetration Test (RCMT)

When it comes to assessing the durability of reinforced concrete, the Rapid Chloride Migration Test (RCMT) has become a preferred method across engineering projects. Unlike RCPT, which measures electrical charge passing through concrete, RCMT evaluates chloride migration under an applied electric field. This approach provides faster and more reliable results, making it a valuable tool for both research laboratories and quality control departments.

Rapid chloride migration test (RCMT) is a test performed for determination of the chloride migration Coefficient in concrete, mortar or cement-based repair Materials from non steady-state migration experiments.

A concrete core of 100 mm diameter and 50 mm thickness is placed inside a rubber sleeve, which separates two compartments, one side is filled with sodium chloride (NaCl) solution (connected to the anode) and the other with sodium hydroxide (NaOH) solution (connected to the cathode). The sample is placed such that the bottom is in contact with the NaCl solution, and the top is in contact with the NaOH solution. An initial voltage of 30V is applied, and the initial current is recorded. Based on this value the RCMT apparatus recommends the next voltage and test duration as per NT BUILD 492. At the end of the test, the final temperature of the system is logged. The concrete sample is then split, and the internal surface is sprayed with silver nitrate.

This reacts with the chloride ions to form a white precipitate, marking the depth of chloride penetration. This depth is used to calculate the chloride migration coefficient, which helps determine the concretes ability to resist chloride-induced corrosion.

Purpose of RCMT in Concrete testing:

The results are crucial for:

Assessing concretes ability to resist migration of chloride ions, which is critical for concrete durability.

Assessing the long-term durability and predicting the service life of concrete structures, especially in environments with high chloride exposure, like coastal regions.

Provides a standardized method to evaluate concretes transport properties, making it useful for both research and construction application.

Evaluating and ensuring the quality of concrete mixes during construction.

Studying the effectiveness of different concrete mix designs and admixtures.

Quality control tool for comparing different mix designs in terms of durability.

Helps in optimizing concrete mix for structures exposed to aggressive environments.

Principle of RCMT:

The Rapid Chloride Migration Test (RCMT), developed under Nordic Concrete Research Framework and standardized as NT BUILD 492, is an electrochemical cell test design conducted to determine the chloride ion migration coefficient of the concrete. The main principle behind this test is the establishment of external applied voltage potential across the specimen which causes the migration of chloride ions through the saturated pore structure of the concrete, which is directly associated with its durability performance in log-term, specially in relation to the chloride induced corrosion of the embedded steel reinforcements (Rebar).

The electrical potential induces a non- steady state migration condition, where the chloride ion transport is primarily by the migration rate rather than concentration driven steady state diffusion.

The test is conducted for a fixed duration typically ranging from 6 to 96 hours. After the test completion the specimen is axially slit, and the internal surface is sprayed by 0.1 M silver nitrate (AgNO3) solution. The silver nitrate reacts with the chloride ions to form silver chloride (AgCl) which appears as a white precipitate marking the penetration depth of chloride. This depth is measured at multiple radial points to calculate the average penetration depth (Xd). The average penetration depth obtained is used in conjunction with other parameters such as applied voltage, initial current, initial and final temperature, and test duration to calculate the non-steady state chloride migration coefficient (Dnssm) as per NT BUILD 492.

The test assumes negligible ion interaction and linear electric potential drop across the specimen. However, other ions may participate in charge transport, although differences in their mobility add negligible interference as the chloride determination is due to selective precipitation reaction between chloride and AgNO3.

This way the RCMT provides a quantifiable and reproducible measurement of chloride ion migration, serving as method for performance based evaluation of different concrete mixes, especially those incorporating supplementary cement materials (SCMs), chemical admixture, or concrete specimens subjected to different curing conditions. The derived migration coefficient serves as an indicator for concretes long-term chloride diffusion behaviour to predict durability of concrete over decades.

Measurement of RCMT:

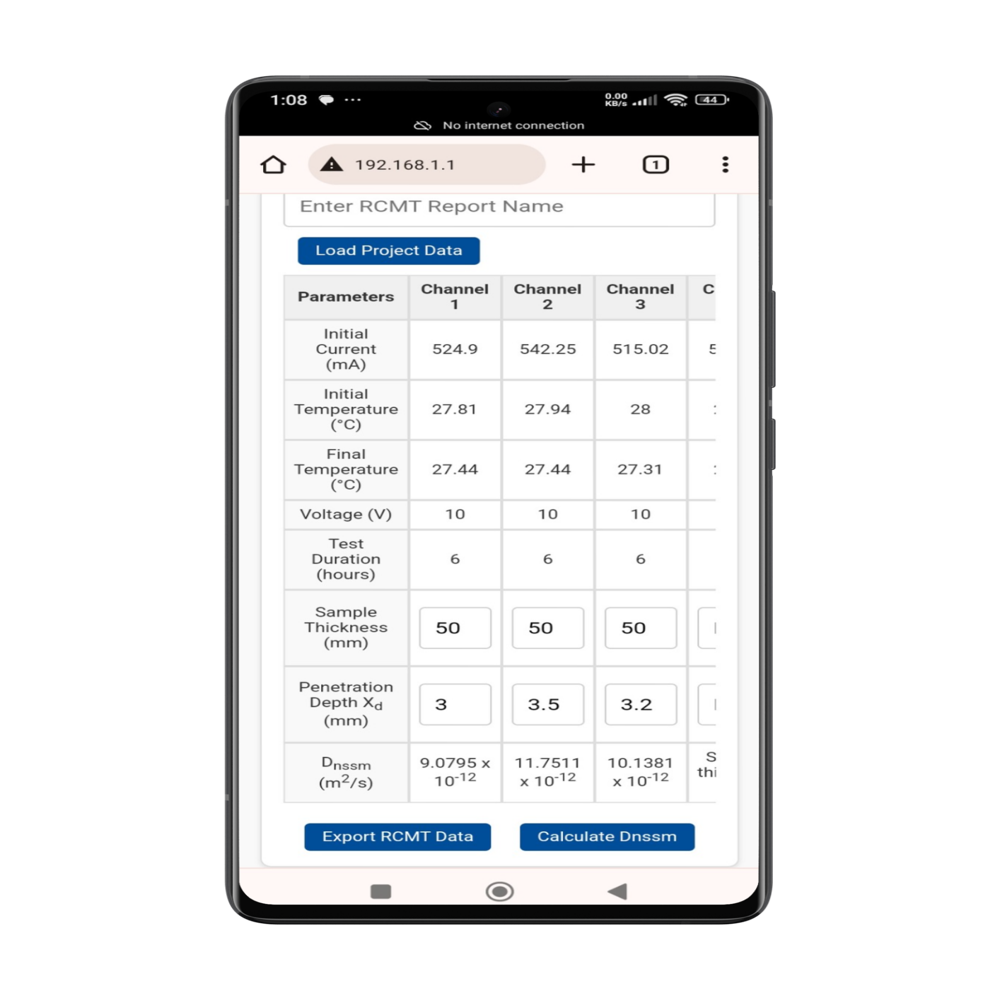

The final calculation combines the average penetration depth with other parameters such as applied voltage, initial current, initial and final temperature, and test duration to calculate the non-steady state chloride migration coefficient (Dnssm) as per NT BUILD 492.

The formula to calculate the non-steady state migration coefficient (as per NT BUILD 492) is given below.

Dnssm = (0.0239*(272+T)*L/(U-2)t) * (Xd * 0.0238 * (273+T)* L * Xd /U-2)

Where:

Dnssm: non-steady-state migration coefficient, m2/s;

z: absolute value of ion valence, for chloride, z = 1;

F: Faraday constant, F = 9.648 104 J/(Vmol);

U: absolute value of the applied voltage, V;

R: gas constant, R = 8.314 J/(Kmol);

T: average value of the initial and final temperatures in the anolyte solution, K;

L: thickness of the specimen, m;

Xd: average value of the penetration depths, m;

t: test duration in hours

Components of RCMT:

Vacuum desiccator and pump: For vacuum saturation of the specimen (<50mbar).

RCMT test Chamber: Holds the concrete specimen and creates chambers for NaCl and NaOH solutions.

Concrete Specimen: The sample to be tested for chloride ion permeability. Cylindrical core of standard dimension 100 mm diameter and 50 mm thickness.

10% Sodium Chloride (NaCl) Solution: Placed in the chamber; source of chloride ions.

0.3 N Sodium Hydroxide (NaOH) Solution: Placed to above specimen in sleeve; completes the electrical circuit.

Silver nitrate, AgNO: Used to spray split specimen surface for chloride penetration detection.

Silicone rubber sleeve: Covers specimen sides; inner/outer diameter.

Stainless steel clamp: Secures sleeve and specimen, prevents leakage.

Electrodes: Transfer electrical current into the solutions.

Power Supply (DC Voltage Source): Provides constant 0-60V across the specimen during the test.

Temperature sensor/ thermocouples: To monitor temperature, accuracy 1C.

Ammeter (Current Meter): Measures the current passing through the specimen to calculate charge passed.

Data Logger / Computer Interface: Records current over time to compute total charge passed (in coulombs).

Standard procedure: Overview (as per NT BUILD 492)

1. Sample Preparation

Concrete specimens are prepared by cutting or coring cylindrical samples of 100 mm diameter and 50 mm thickness (2 mm). These are typically taken from cast cubes, cylinders, or field cores. The side surfaces are sealed using rubber sleeves, epoxy, or similar material to ensure that chloride can only enter the concrete from the exposed circular faces. Specimens should be cured for a minimum of 28 days, and surface carbonation or contamination should be removed before testing.

2. Preconditioning / Saturation

To ensure accurate and repeatable results, the specimen must be fully saturated. This is done using a vacuum saturation method where the specimens are placed in a container filled with saturated calcium hydroxide [Ca(OH)] solution. A vacuum (50 mm of Hg) is applied for 3 hours to remove air from the concrete pores. After the vacuum is released, the specimens remain submerged in the solution for an additional 18 2 hours. This step ensures the pore system is completely filled with liquid, simulating worst-case chloride ingress conditions.

3. Test Assembly

The saturated specimen is mounted in a migration cell, with its ends exposed to two different solutions, Cathode chamber (negative side) is filled with 10% NaCl (sodium chloride) solution. The Anode chamber (positive side) is filled with 0.3 N NaOH (sodium hydroxide) solution. Each chamber contains a stainless steel electrode (plate or mesh), and the entire setup is sealed to prevent leakage. The arrangement ensures unidirectional ion movement through the concrete.

4. Applying the Electric Field

Initially 30 volts DC is applied across the specimen using an external power supply. The test duration ranges from 6 to 96 hours, depending on initial current value. The electric field forces chloride ions to migrate from the catholyte (NaCl) into the concrete. During the test, the initial current, temperature, and voltage are recorded.

5. Splitting and Chloride Detection

After the test completion, the specimen is removed and split axially to expose the internal surface. The freshly split face is sprayed with 0.1 M silver nitrate (AgNO) solution. This reacts with any chlorides present, forming a white precipitate of silver chloride, clearly showing the depth of chloride penetration.

6. Measurement of Chloride Migration

Using a scale, the depth of the white chloride front is measured at ten evenly spaced points across the diameter of the specimen. The average penetration depth (Xd) is calculated from these readings, which serves as a basis for computing the chloride migration coefficient.

7. Calculation of Migration Coefficient

The chloride migration coefficient (Dnssm) is calculated using a standard equation provided in NT BUILD 492. The formula uses inputs such as the average penetration depth, test voltage, duration, specimen thickness, and temperature. This coefficient quantifies the rate of chloride migration under test conditions and serves as a key indicator of concrete durability.

Result Interpretation of RCMT:

The main results of the RCMT is the chloride migration coefficient (Dnssm), which is expressed in:

x * 10(-12) m2/s

Lower values represent better resistance to chloride penetration, which corresponds to higher durability.

While NT BUILD 492 provides the procedure and the formula for calculating the non-steady state chloride migration coefficient (Dnssm), it does not define specific limits for durability classification. Therefore, the interpretation of the results must be done by referring to relevant research literature or guidelines provided by other institutions.

Factors influencing RCMT results:

Influence of Moisture Content: The test results are highly affected by the moisture content, and may lead to current fluctuations ultimately skewing the final results of the test.

Effect of Admixtures: Use of chemical or supplementary cementitious materials (SCMs) like silica fume, fly ash may reduce the pore size of the concrete sample, increasing the resistance to movement of chloride ion.

Pore structure and connectivity: The size , distribution, and inter connectivity of pores determine how easily chloride ions can move through the concrete.

Temperature effect: Rise in temperature increases the diffusion rate of the chloride ions, leading to higher measured migration of the chloride ions. It also affects the micro-structures in the concrete changing the final result, leading to false interpretation.

Sources of Error in RCPT:

1. Improper sample conditioning: Inadequate sample conditioning can leave air pockets in deeper pore, reducing the overall charge migration.

2. Specimen size: Inconsistent specimen size, thickness or surface area can affect the resistance and the chloride ion passage in the sample.

3. Poor sealing of leakage: If the specimen is not sealed properly or the setup leaks, passage of the chloride ions may bypass the specimen, leading to false interpretation or underestimation of the results.

4. Inconsistent voltage supply: The standard voltage for the test depends on the initial current value, referring to the next voltage that is set. Any deviation or fluctuation in the input voltage throughout the test can generate invalid results.

5. Temperature variations: Changes in the temperature in the cell during the test can influence the current flow and chloride ion migration.

6. Contamination of Electrolytic solutions: Contamination in both sodium chloride (NaCl) and Sodium Hydroxide (NaOH), can affect the ionic strength of the solutions, ultimately affecting the current flow and charge movement.

7. Incorrect Depth Measurement: The penetration depth of the chloride is measured after spraying silver nitrate. Improper measurement or uneven spraying can lead to incorrect interpretation of migration depth.

8. Operator Error: Any kind of human error in setting up the test, noting down the measurements or miscalculation can cause significant discrepancies in the validity of the result.

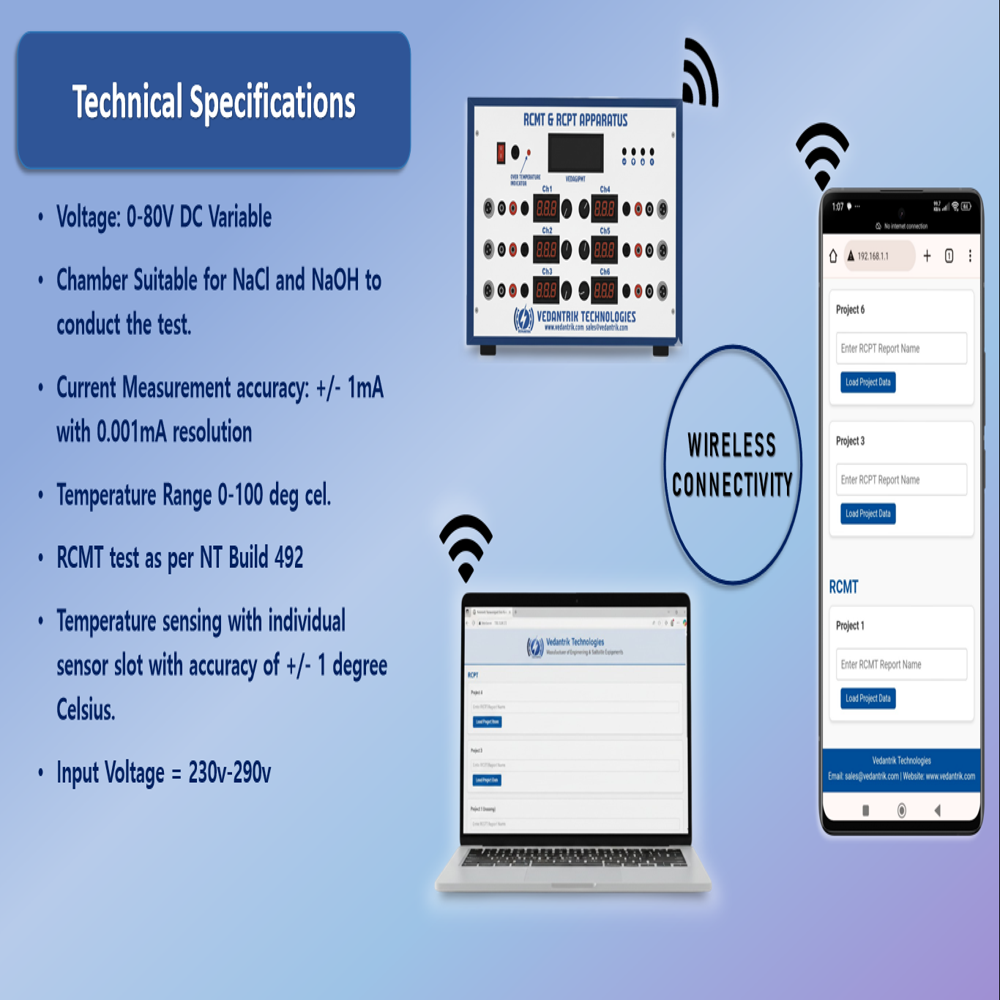

Rapid Chloride Migration Test (RCMT) Apparatus by Vedantrik Technologies

Durability of concrete depends on its resistance to chloride ingress, and the Rapid Chloride Migration Test (RCMT) is one of the most effective methods to measure it. Unlike traditional long-duration permeability tests, RCMT delivers quicker results by monitoring the migration of chloride ions under an applied electric field. This makes it a practical choice for both research laboratories and on-site quality control.

Rapid chloride migration test (RCMT) apparatus by Vedantrik Technologies is laboratory device specially made for determination of the chloride migration Coefficient in concrete, mortar or cement- based repair Materials from non-steady-state migration experiments. A concrete core of 100 mm diameter and 50 mm thickness is placed inside a rubber sleeve, which separates two compartments, one side is filled with sodium chloride (NaCl) solution (connected to the anode) and the other with sodium hydroxide (NaOH) solution (connected to the cathode). The sample is placed such that the bottom is in contact with the NaCl solution, and the top is in contact with the NaOH solution. An initial voltage of 30V is applied, and the initial current is recorded. Based on this value the RCMT apparatus automatically recommends the next voltage and test duration as per NT BUILD 492

At the end of the test, the machine logs the final temperature of the system. The concrete sample is then split, and the internal surface is sprayed with silver nitrate. This reacts with the chloride ions to form a white precipitate, marking the depth of chloride penetration. This depth is used to calculate the chloride migration coefficient, which helps determine the concretes ability to resist chloride-induced corrosion. The RCMT machine is available in different channel options3, 4, 6, 8, or 12to allow multiple samples to be tested simultaneously.

Key Features of Vedantrik RCPT Apparatus

Protection against power cut: Any power interruption during the test can affect the results. However, Vedantrik RCMT is equipped with an intelligent power recovery system that automatically tracks the progress and resumes the test from the exact point of interruption.

Automated voltage & test duration recommendation: Based on the initial current value the Vedantrick RCMT automatically calculates and recommends the next voltage along with total test duration.

Automatic final temperature capture: In RCMT both the initial and final temperature are required in the final calculation. To simplify the process Vedantrik RCMT apparatus automatically logs the final temperature value at the conclusion of each test.

In-built voltage stabilizer: Vedantrik RCMT features an advanced micro-controller based power electronics for precise voltage regulation.

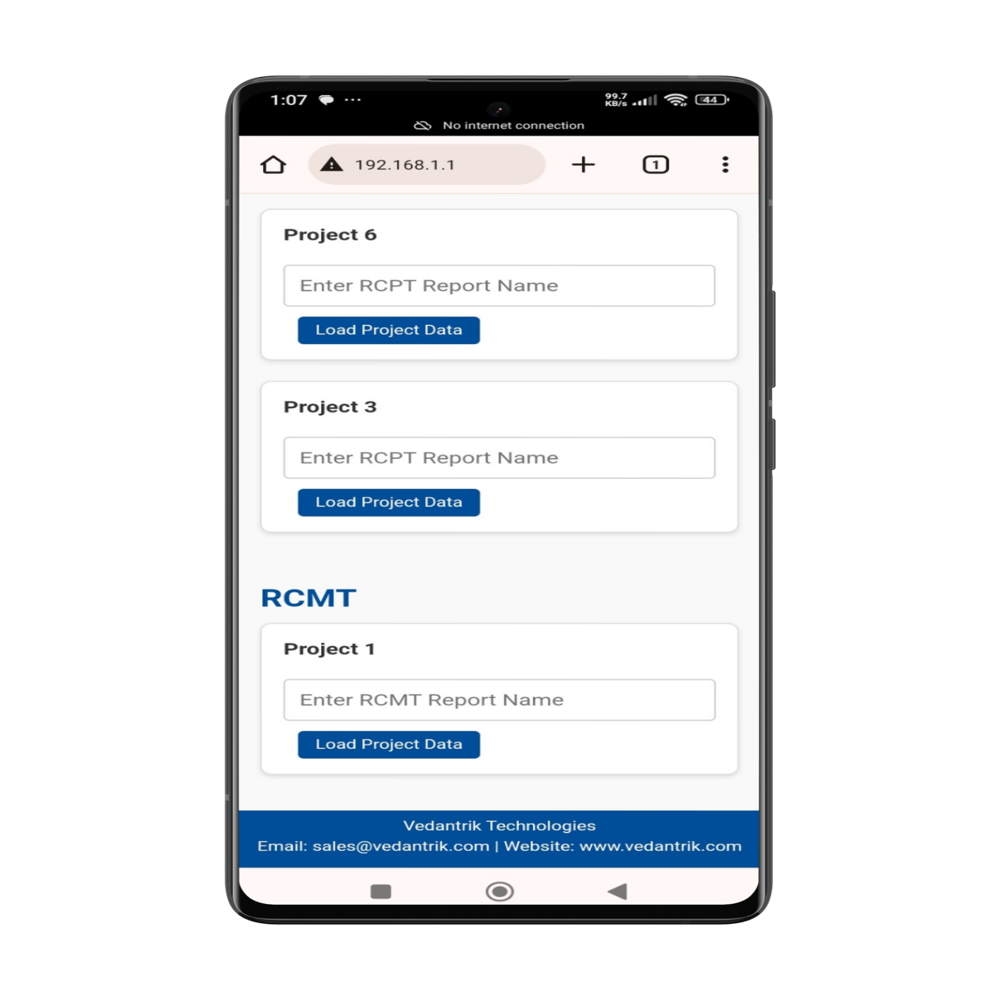

Uninterrupted wireless connectivity:Vedantrik RCPT equipment features wireless connectivity, typically via in-built Hotspot, which allows for remote data access.

Multi-device compatibility:Vedantrik RCPT wireless feature is compatible with a range of devices, including PCs, laptops, Android mobile phones, and iPhones, ensuring that users can access and share data regardless of their operating system.

Protection: Vedantrik RCPT apparatus provides short circuit and over current over voltage protection.

Web-based software: Vedantrik RCMT comes with powerful web-based software that can be accessed by connecting via Hotspot with a range of devices, including PCs, laptops, Android mobile phones, and iPhones to access the data in real time.

In-built data acquisition system: Vedantrik RCMT features in-built data acquisition system that captures and stores all the test data, without the need for internet connection.

In Mumbais construction industry, where large-scale infrastructure projects require high standards of durability, RCMT helps ensure concrete can withstand aggressive environments. At Vedantrik Technologies, advanced RCMT testing equipment is developed to support engineers in achieving accurate results that comply with global standards. With user-friendly interfaces, precise control systems, and dependable output, their instruments have become a trusted choice for builders and testing labs.

RCMT plays a vital role in evaluating how effectively supplementary cementitious materials and admixtures improve resistance to chloride penetration. By integrating RCMT in routine quality checks, engineers can make informed decisions about mix design, durability enhancement, and long-term cost savings.

For reliable RCMT equipment in Mumbai, partner with Vedantrik Technologies. Get in touch today to explore solutions that ensure your concrete structures remain strong and corrosion-resistant for decades.

Technical Specifications:

Voltage: 0-80V DC 0.1V

Current measurement accuracy: 1mA

Tank suitable for NaCl and NaOH to conduct RCMT as per NT Build 492.

Ambient Temperature: 20-25C.

Temperature sensing with individual sensor slot accuracy 1C.

Input Voltage: 230V-265V.

As a best RCMT Rapid Chloride Migration Test system manufacturer in India we have supplied in Mumbai, Pune, Nashik, Aurangabad, Surat, Vadodara, Ahmedabad, Indore, Bhopal, Nagpur, Jaipur, Ludhiana, Ghaziabad, Delhi, Lucknow, Kanpur, Prayagraj, Patna, Ranchi, Dhanbad, Bengaluru, Hyderabad, Chennai, Coimbatore, Madurai, Visakhapatnam, Kolkata, and Srinagar.

Also we have supplied a range of products in Dubai, Abu Dhabi, the United Arab Emirates, Oman, Saudi Arabia, Kuwait, and Iran. We also serve clients in Singapore, Indonesia, Thailand, and other international locations.

Price:

Price 195000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Mild Steel

Frequency : 50 hz Hertz (HZ)

Color : Blue

Power Supply : Electric

Price 195000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Mild Steel

Frequency : 50 Hertz (HZ)

Color : Blue

Power Supply : Electric

Price 195000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Mild Steel

Frequency : 5060 Hertz (HZ)

Color : Blue

Power Supply : Electric